In the ever-evolving world of material science, one company stands out with its innovative approach and dedication to quality—Custom Materials Inc. As leaders in custom fabrication and custom manufacturing, they are setting new standards in the industry. This article explores how Custom Materials Inc is making waves and revolutionizing the field. Choose the best Custom Materials Inc.

Founded with a vision to transform the material science industry, Custom Materials Inc started its journey with a small team of passionate experts. Their goal was clear: to develop and supply materials that meet the unique needs of various industries. Over the years, they have grown into a powerhouse of innovation and excellence.

Visionary Beginnings

The inception of Custom Materials Inc was driven by a bold vision to disrupt traditional practices in material science. The founders, a group of seasoned engineers and scientists, recognized a gap in the market for customized solutions that could adapt to the rapidly changing demands of modern industries. Their early projects were focused on understanding client-specific challenges and tailoring solutions that could address these effectively.

Building a Team of Pioneers

From its inception, Custom Materials Inc prioritized assembling a team of pioneers. Recruiting top talent from diverse fields such as engineering, chemistry, and design, they cultivated a multidisciplinary environment that fostered innovation. This diverse expertise allowed them to approach problems from multiple angles, ensuring comprehensive solutions.

Growth and Expansion

Custom Materials Inc’s commitment to quality and innovation quickly propelled them from a small startup to a major player in the industry. By strategically expanding their operations and investing in state-of-the-art facilities, they were able to increase their capacity and take on larger projects. This growth also included forming strategic partnerships with key players across various sectors, further solidifying their industry presence.

A Commitment to Innovation

The core of Custom Materials Inc’s philosophy is innovation. They understand that in order to stay ahead, constant research and development are necessary. By investing heavily in cutting-edge technologies, they are able to offer solutions that are not only effective but also sustainable.

Investing in Research and Development

Research and development (R&D) are the lifeblood of Custom Materials Inc’s innovation strategy. The company allocates a significant portion of its budget to R&D efforts, ensuring they remain at the forefront of technological advancements. This investment not only fuels the creation of new materials but also enhances existing processes, making them more efficient and environmentally friendly.

Embracing Emerging Technologies

Custom Materials Inc is a firm believer in the potential of emerging technologies. They actively explore areas such as nanotechnology, 3D printing, and advanced composites to develop groundbreaking materials. By staying abreast of technological trends, they are able to anticipate industry needs and create products that meet the future demands of their clients.

Collaboration with Academia and Industry

To bolster their innovation efforts, Custom Materials Inc collaborates closely with academic institutions and industry leaders. These partnerships facilitate knowledge exchange and provide access to the latest research findings. Such collaborations also open up opportunities for joint ventures and co-development projects, further driving innovation within the company.

The Custom Fabrication Advantage

Custom fabrication is more than just a service at Custom Materials Inc; it is a cornerstone of their business. By tailoring materials to meet specific requirements, they provide their clients with unparalleled flexibility and precision.

Tailored Solutions for Every Industry

Custom Materials Inc serves a wide range of industries, including aerospace, automotive, electronics, and construction. Each sector has its own unique demands, and Custom Materials Inc excels in crafting solutions that address these challenges head-on. Whether it’s developing lightweight composites for aerospace or durable materials for construction, they have the expertise to deliver.

Aerospace Innovations

In the aerospace industry, weight reduction is paramount. Custom Materials Inc has pioneered the development of lightweight, high-strength composites that significantly reduce aircraft weight without compromising safety. These materials contribute to improved fuel efficiency and lower carbon emissions, addressing both economic and environmental concerns.

Automotive Advancements

The automotive sector benefits from Custom Materials Inc’s ability to produce materials that enhance vehicle performance and safety. Their custom solutions include impact-resistant materials for car bodies and innovative thermal management systems for electric vehicles, demonstrating their capability to address diverse automotive needs.

Electronics and Consumer Goods

For the electronics industry, Custom Materials Inc creates materials that enhance conductivity and durability. Their innovations extend to consumer goods, where they develop materials that improve product longevity and user experience. This versatility ensures that they remain a trusted partner across various markets.

State-of-the-Art Technology

One of the key factors that sets Custom Materials Inc apart is their use of state-of-the-art technology in custom fabrication. With advanced machinery and skilled technicians, they ensure that every product meets the highest standards of quality and accuracy.

Precision Engineering

Custom Materials Inc utilizes precision engineering techniques to create materials with exact specifications. By employing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, they ensure that every product is crafted with unparalleled accuracy. This precision is critical in sectors where even the slightest deviation can have significant consequences.

Advanced Manufacturing Techniques

The company continuously explores advanced manufacturing techniques such as additive manufacturing and laser cutting. These methods allow for the creation of complex geometries and intricate designs that traditional methods cannot achieve. This flexibility enables them to deliver customized solutions that are both innovative and functional.

Skilled Workforce

At the heart of Custom Materials Inc’s technological prowess is a skilled workforce. Their technicians and engineers undergo continuous training to stay updated on the latest technologies and methodologies. This commitment to workforce development ensures that they maintain their competitive edge and consistently deliver high-quality products.

Excellence in Custom Manufacturing

Custom manufacturing at Custom Materials Inc is driven by a commitment to excellence. By focusing on quality control and precision, they ensure that every product not only meets but exceeds customer expectations.

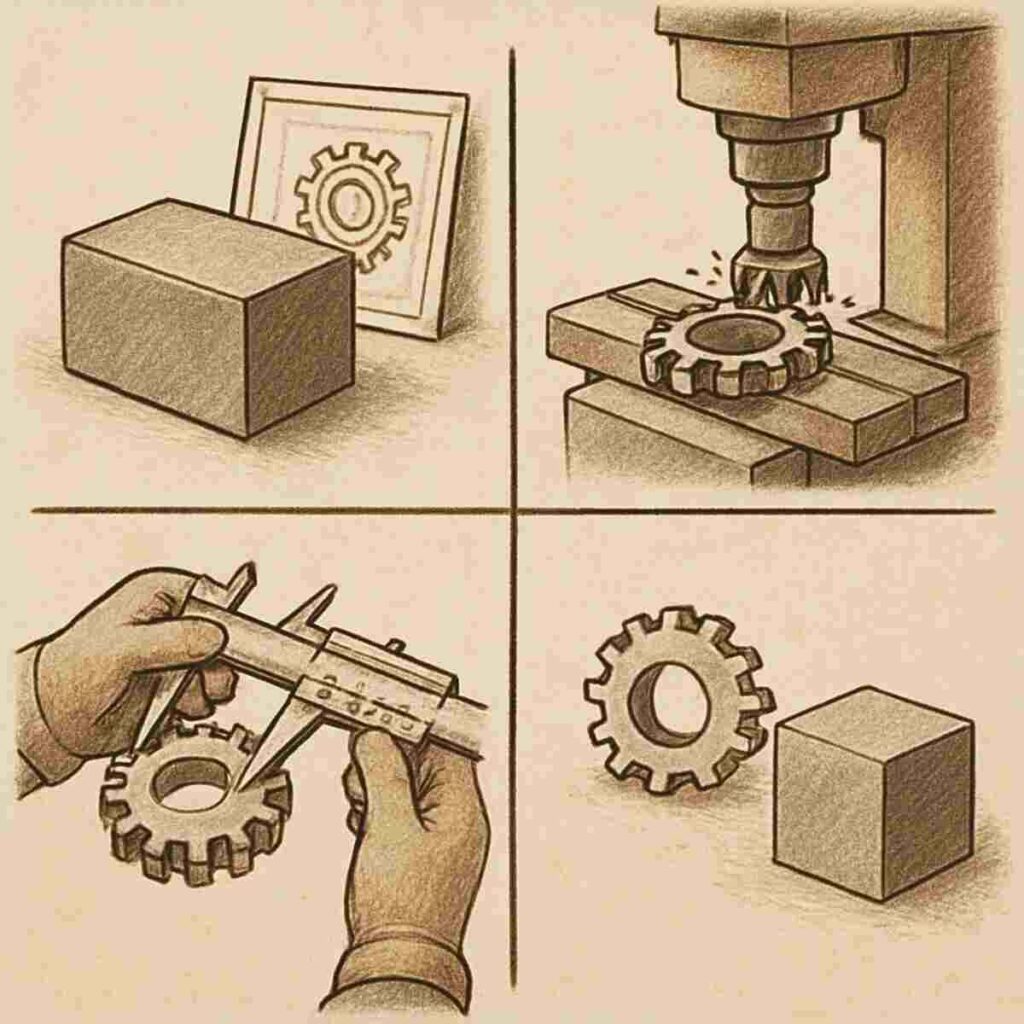

From Concept to Completion

The journey of custom manufacturing begins with a concept. At Custom Materials Inc, they work closely with their clients to understand their vision and requirements. This collaborative approach ensures that the final product is a perfect match for the client’s needs.

Collaborative Design Process

Custom Materials Inc’s design process is highly collaborative. They engage clients in every step, from initial brainstorming to final design approval. This ensures that all client requirements are met and that the final product aligns with their strategic goals.

Prototyping and Testing

Once a concept is finalized, the company moves to prototyping and testing. This phase involves creating a working model that undergoes rigorous testing to ensure it meets all specifications. Feedback from this stage is used to refine the product, ensuring optimal performance and reliability.

Seamless Production Integration

After successful prototyping, Custom Materials Inc integrates the design into full-scale production. Their seamless transition from design to manufacturing minimizes lead times and ensures that products are delivered on schedule, meeting client expectations for quality and timeliness.

Quality Control at Every Stage

To maintain their reputation for excellence, Custom Materials Inc implements rigorous quality control measures at every stage of the manufacturing process. From raw material selection to final inspection, every step is meticulously monitored to guarantee the highest quality outcome.

Stringent Raw Material Selection

The manufacturing process at Custom Materials Inc begins with the careful selection of raw materials. Only the highest quality materials are chosen, ensuring that the final products are durable and reliable. This meticulous selection process is a cornerstone of their quality assurance strategy.

Continuous Monitoring and Inspection

Throughout the manufacturing process, products are subject to continuous monitoring and inspection. Advanced sensors and automated systems are used to track production metrics and identify any deviations from specified standards. This real-time monitoring enables quick corrective actions, maintaining product integrity.

Final Product Certification

Before products are shipped to clients, they undergo a final certification process. This includes comprehensive testing and validation to ensure that they meet all regulatory and client-specific standards. This final step is crucial in maintaining client trust and satisfaction.

The Impact of Custom Materials Inc

Custom Materials Inc’s influence extends beyond their innovative products and services. They are also committed to sustainability and community engagement, making a positive impact on both the environment and society.

Sustainable Practices

Sustainability is a core value at Custom Materials Inc. They are dedicated to minimizing their environmental footprint by using eco-friendly materials and processes. Their commitment to sustainability not only benefits the planet but also sets an example for others in the industry.

Eco-Friendly Material Sourcing

Custom Materials Inc prioritizes sourcing materials that have minimal environmental impact. By choosing suppliers who adhere to sustainable practices, they ensure that their supply chain is as green as possible. This focus on eco-friendly sourcing is a key component of their sustainability strategy.

Waste Reduction Initiatives

The company actively seeks to reduce waste in its manufacturing processes. This includes implementing recycling programs and designing processes that minimize material waste. These initiatives not only reduce costs but also contribute to their environmental stewardship goals.

Energy Efficiency Measures

Custom Materials Inc invests in energy-efficient technologies to reduce their carbon footprint. From utilizing renewable energy sources to optimizing machinery for lower energy consumption, they are committed to reducing their environmental impact through responsible energy use.

Community Engagement

Custom Materials Inc believes in giving back to the community. Through various initiatives, they support local projects and organizations, contributing to the betterment of society. Their dedication to community engagement reflects their belief in the importance of corporate social responsibility.

Educational Outreach Programs

The company is passionate about fostering the next generation of material scientists and engineers. They sponsor educational outreach programs that provide students with hands-on experience and exposure to cutting-edge technologies. These programs inspire young minds and encourage them to pursue careers in STEM fields.

Local Partnerships and Support

Custom Materials Inc actively partners with local businesses and non-profits to support community development. These partnerships focus on creating sustainable economic opportunities and improving quality of life for local residents. Their involvement in local initiatives underscores their commitment to corporate citizenship.

Employee Volunteerism

Employees at Custom Materials Inc are encouraged to participate in volunteer activities. The company provides paid time off for volunteer work, allowing employees to contribute to causes they are passionate about. This culture of volunteerism strengthens community bonds and enhances the company’s reputation as a socially responsible organization.

The Future of Custom Materials Inc

Looking ahead, Custom Materials Inc is poised for continued growth and innovation. With a focus on developing new materials and expanding their global reach, they are set to maintain their position as leaders in the material science industry.

Expanding Global Presence

Custom Materials Inc is not content with resting on their laurels. They are actively pursuing opportunities to expand their presence in international markets. By establishing partnerships and exploring new regions, they aim to bring their innovative solutions to a wider audience.

Strategic International Partnerships

To facilitate global expansion, Custom Materials Inc is forming strategic partnerships with international firms. These alliances enable them to leverage local expertise and navigate complex regulatory environments. This collaborative approach is key to their success in new markets.

Exploring Emerging Markets

The company is keenly focused on exploring emerging markets with high growth potential. By understanding local needs and adapting their offerings accordingly, they aim to capture market share and establish a strong foothold in these regions. This strategy positions them for long-term success on a global scale.

Enhancing Supply Chain Capabilities

As they expand globally, Custom Materials Inc is enhancing their supply chain capabilities. This includes investing in logistics infrastructure and adopting advanced supply chain technologies to ensure efficient and reliable delivery of their products worldwide. These enhancements support their international growth objectives.

Pioneering New Materials

Research and development remain at the heart of Custom Materials Inc’s strategy. They are constantly exploring new materials and technologies to meet the evolving needs of their clients. This forward-thinking approach ensures that they stay at the forefront of the industry.

Breakthrough Material Innovations

The company is dedicated to pioneering breakthrough materials that redefine industry standards. By pushing the boundaries of material science, they are developing products that offer superior performance and sustainability. These innovations are key to maintaining their competitive edge.

Adapting to Industry Trends

Custom Materials Inc closely monitors industry trends to anticipate future demands. This proactive approach allows them to adapt their R&D efforts to align with market needs, ensuring they continue to deliver relevant and impactful solutions.

Cross-Disciplinary Research Initiatives

To drive material innovation, Custom Materials Inc engages in cross-disciplinary research initiatives. By bringing together experts from different fields, they foster a collaborative environment that encourages creative problem-solving and the development of novel materials.

Conclusion

Custom Materials Inc is more than just a company; it is a driving force in the world of material science. Through their commitment to innovation, quality, and sustainability, they are revolutionizing the industry. As they continue to push boundaries and explore new frontiers, Custom Materials Inc is set to shape the future of material science for years to come.

In conclusion, whether you are in need of custom fabrication, custom manufacturing, or simply want to learn more about cutting-edge materials, Custom Materials Inc offers the solutions you need with a commitment to excellence that sets them apart. Their innovative spirit and dedication to sustainability make them a leader in the field, poised to influence the material science landscape for generations.